- publication

- ACM CHI 2021

- authors

- Madlaina Signer, Alexandra Ion, Olga Sorkine-Hornung

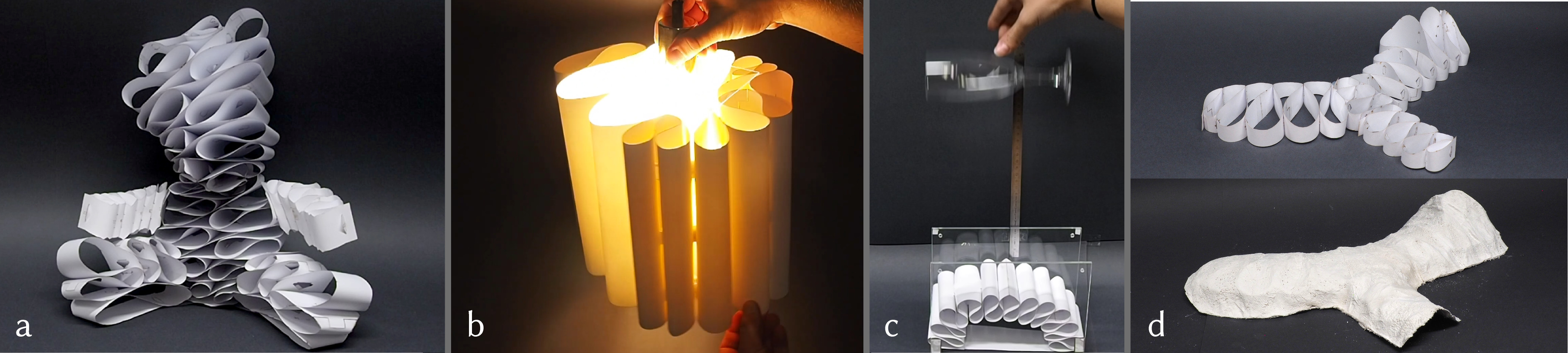

We propose a novel material design that can be laser cut with user-defined compliance. We show how such fast to produce materials allow users to create custom materials, such as (a) stuffing for toys with custom softness, (b) lamp shades with variable transparency, (c) damping materials for packaging, or (d) be used for static support (e.g., formwork for architecture).

abstract

We propose a novel design of engineered, structured materials that leverages fast fabrication technologies, pushing them towards mass-fabrication. Specifically, our metamaterial is designed to be laser cut, to approximate the volumetric shape and allow for locally varying compliance. Traditional mechanical metamaterials consist of intricate cells arranged on a 3-dimensional grid, limiting them to 3D printing; which is slow. Our metamaterial is designed for laser cutting, which is drastically faster. Our structures are best described as ruffled strips of thin sheet material, such as paper, plastics, metals, etc. Users can interactively define the ruffles' anisotropic stiffness directions and local density. Our computational design tool assists users by automatically optimizing the ruffle to fill the shape's volume, and exporting the flat ruffle design ready for cutting. We demonstrate how such ruffled metamaterials can be utilized for, e.g., custom toys with locally varying compliance, custom packaging material, or lightweight formwork for architectural shells.

downloads

videos

acknowledgments

We thank Philipp Herholz for his helpful advice about the simulation and David Lindlbauer for providing feedback on the paper and for his help with the figures and video. This work was in part supported by the Swiss National Science Foundation (NCCR Digital Fabrication Agreement #51NF40-182887).